How To Repair Led Light Strip

This back up page offers a comprehensive hands-on guide, explaining why your LED strip lights are non working and how to fix them.

NOTE: These troubleshooting instructions employ to LED strips from any manufacturer/supplier, non just strip lights purchased from InStyle LED. (In fact, our LED strip lights employ the very highest-quality components, and then they're extra reliable and fully backed with a 5 twelvemonth warranty so please check us out!)

Overview:

If your LED strip lights are non working, at that place may exist many different reasons why. But in every case, the starting time step is to find where the trouble is located. Once you know that, it becomes much more than simple to assess the nature of the fault and how to repair/resolve it.

This guide covers troubleshooting for all LED strips that run on 12V or 24V. That includes white, single-color , RGB, RGBW and dual-white LEDs.

Quick links:

Trouble: MY LEDS ARE FLASHING

Reason:

If your LEDs are flashing in a regular, consistent sequence (e.grand., on for 1 2nd, off for one 2d, then on for 1 second once more), then your ability supply is overloaded! This means you have as well much striplighting connected to that power supply.

For example, if you have 10m of LED strip that draws 5 watts per metre, the strip requires 50W in total (whether information technology'southward 2 5m strips or 10x 1m strips, information technology still adds up to 50W). If those strips are all powered by a 30W power supply, this will go into overload protection mode, which ways information technology will turn on, realise it is overloaded and immediately turn back off again, then keep repeating this cycle.

You may chose to get a larger power supply that tin can handle the total wattage required, so a power supply higher that the total wattage of all your LED strips.

Or you could get some other power supply of the same size every bit you lot already have, and split up the strips across 2 power supplies.

Or mayhap your project volition let you to reduce the amount of strips onto that ability supply.

Here is a great video to piece of work out how much strip you can put on a power supply:

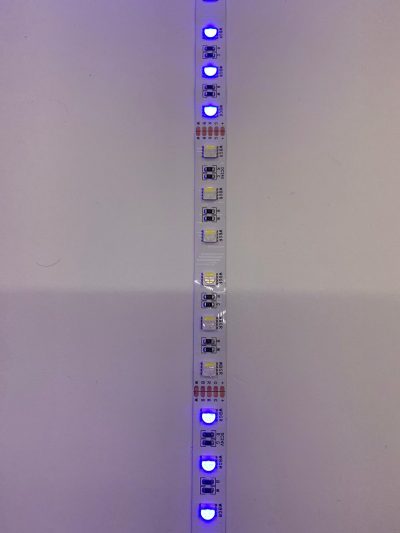

Trouble: MY RGB/RGBW LEDS ARE SHOWING A DIFFERENT COLOUR IN SOME Minor SECTIONS OF THE STRIP (e.g., 100mm not working)

Reason:

Are your LED strips working fine for virtually of their length, except for one department or a couple of sections within the cutpoints of the tape? (e.g., when you select Orange, a 50mm or 100mm section shows Greenish simply.) Well that ways the Cerise LEDs inside that department are faulty. You tin can easily confirm this – if y'all set the strips to just Red so on that section they will be completely unlit, and if yous set to Purple that section will show Blueish only.

This tin can be very confusing when yous install your first LED project and see these colours not matching. Just the respond is simply that one color of the RGB/W LEDs is not working within that section and needs replacing. This can be caused by static-electricity impairment, or bending and twisting the strip too much, or being trod on, damaged in transit, a cheap poor-quality strip, or dry solder joints.

LED strips are made up of 50mm / 100mm sections (sometimes other sizes), and wired in a way that means each section is a detached, enclosed circuit (in other words, if a LED or resistor is damaged it will simply effect the department of strip within the cutpoints).

If the complete section between cutpoints is not working, this is a very like problem to a damaged LED or resistor – most probable caused by a dry solder joint.

Solution:

In most cases here the but option is to supervene upon that section of the strip. Y'all can do this by swapping the full strip. Or y'all can get another, say for instance, 100mm section and solder this in – or you lot tin can employ connector clips to clip in a new 100mm section.

Before taking this step, it's worth attempting to bear upon or printing down on the LEDs/resistors in the faulty section – in the best case possible, you may come across that the light miraculously comes back on; in this instance the problem is a dry out solder joint, and if you're capable of soldering you tin can repair this strip!

Video walkthrough :

Trouble: MY RGB/RGBW LEDS ARE SHOWING A Unlike Color (full color is affected or non working)

Reason:

If all of the LED strips colours are working except for but one colour, and this is affecting that colour all along the strip (e.g., the whole length of the Red colour LEDs are not working), and then there is either a fault with the soldering of the Red -ve cablevision onto the strip'south PCB, or else Red cable is faulty from the strip to the receiver, or the connectedness of the Red cable into the receiver is faulty or disconnected.

We can say this with some certainty, considering here is no manner that full length of Cherry-red LEDs are all faulty; the style LED strips are made means that a faulty LED volition just affect the section between those cut points. Therefore the event is related to the cabling.

Solution:

Check the cables betwixt the controller and the strip, especially if you have extended them with a connector block. An effective examination would be to wire the power supply directly to the strip, thus cutting out any extension cables and any command gear. And note that blackness is always positive (+) for RGB/RGBW strips. so offset by wiring the positive from the power supply to the black cable on the LED strip. Then wire the -ve from the power supply to the cable for the colour that isn't working.

Allow'due south imagine that it'southward the blue cablevision that is not working. In such a case, yous should and so see that the Blue lights will light up, proving that they work – which ways you lot have a bad connection somewhere else. With this knowledge in mind, rebuild the system step-by-step, calculation the controller (and extension cables if you have them) and run across which component makes the Bluish lights stop working.

(If at this betoken the Bluish does not work at all, then check if its cablevision has come off the solder pad on the strip, as this is the only reason left as to why it would not work.)

Problem: MY LEDS ARE VERY HOT TO Impact – ALMOST Called-for

Reason:

This problem has two possible causes. Either (A) You y'all have a 24V power supply connected to 12V LED strips. Or (B) at that place is a 'short' along the strip – in other words the solder has gone across the PCB somewhere and the +ve and -ve are touching, shorting the circuit. Or if you lot have an output cable, the output +ve and -ve may be touching.

If selection A is true, with 24 volts going to a 12V strip, then yes the strips volition still work. They will in fact be brighter than they should be, equally yous accept double the power going through. Just the trouble is that this will damage the LEDs very quickly (usually within hours) and can be a burn hazard.

The aforementioned with selection B: if +ve and -ve and are touching somewhere, then the strips will neglect within hours and LEDs will exist exist damaged. Yous may fifty-fifty olfactory property burning and this could be a fire hazard,

Solution:

If yous accept a 24V power supply going to 12V strips, yous can resolve this by getting a 12V power supply, or you can find a converter that converts 24V down to 12V (this would wire in between the power supply and the strip).

If you take a 'short', you will need to thoroughly check every single part of the strip close upwardly and see if any solder is going across the connections. If so, then you can either resolder, or only separate the solder with a Stanley knife so that the +ve and -ve are no longer touching.

Video walkthrough :

Problem: MY LED STRIPS ARE TRIPPING MY BREAKER

Reason:

This tin can exist caused by two things. You may have a faulty power supply. Or else the inrush current is too high for your breaker.

Solution:

If you suspect a faulty ability supply, test it by removing all the power supplies yous take on the breaker and try reconnecting them, one at a fourth dimension – calculation some other until the breaker trips. Then you know which one is faulty.

If you lot don't have a faulty power supply simply have several ability supplies on a breaker and it is tripping, then the inrush current is besides loftier for that type of breaker. You lot volition accept to increase the breaker size. If it is yet tripping, then look into splitting the power supplies across different breakers.

Video walkthrough :

Problem: MY LEDS ARE LESS Vivid TOWARDS THE END (slow, uneven brightness)

Reason:

Yous have voltage drop across the strip.

Solution:

Nearly standard LED strips can be used in lengths upwardly to 5m, powered from 1 end, with no voltage drop along the strip that will be visible to the homo eye. (some specialised strips can exist used in 10m,15m or 20m lengths).

And so if, for case, you have joined two x 5m strips together and powered them from i end and the strip is less bright towards the finish, then y'all should either: (A) spit the strip up and wire the 2 x 5m strips in parallel, or (B) wire in a ring main with a starter pb and exit lead on the 10m and wire both cables back to the 1 ability supply, as shown below.

Video walkthrough 1 (voltage driblet) :

Video walkthrough 2 (wiring options) :

Problem: MY LEDS SMELL Similar THEY'RE BURNING – WHEN LEFT COILED Upwardly

Reason:

If the LED strips are powered up when left on the reel provided or withal coiled up, then the build upward of the estrus will crusade them to go extremely hot and burn out.

Solution:

Only always examination strips when they are uncoiled. They must non be coiled up in whatever way.

Video walkthrough :

Trouble: MY STRIPS ARE SHOWING INCONSISTENT COLOURS IN PATCHES (due east.g., cool white strips are showing warm white in sections)

Reason:

You have pigment on them! Very simply I accept seen this upshot hundreds of times, if you have a cool white strip then in random sections of, perhaps, 50mm you see warm white (or they announced to exist completely 'off') then this is because they have been painted on.

This happens a lot when the painters come in and paint and do not know that in that location are LED strips where they cannot meet them (inside a coving, for example). And then when you turn them on, bam! – you lot come across the faults.

Solution:

Depending on how much paint there is, the strips tin can sometimes be saved! Y'all can wipe the paint off the strips. Do not use whatever water-based products or that will damage the LEDs. You tin can likewise scrape the dry paint off the LEDs with a fine knife. Make sure the strips are turned off. I have washed this successfully many times, and the strips worked perfectly afterwards.

Video walkthrough :

Problem: MY LEDS WILL Not Lite UP AT ALL

Reason:

If the LEDs volition not light up at all, then this could be down to a faulty power supply.

Solution:

If you take several power supplies, then endeavour a different power supply onto the same strip to see if this now works. If information technology does, then you take a faulty ability supply and will demand a new one.

Problem: MY RGB/W LEDS ARE ONLY LIGHTING UP A Low (RED) GLOW

Reason:

Y'all accept a 12V power supply going to 24V LED strips.

Solution:

The only option here is to get a replacement 24v power supply for your 24v strips.

Problem: WHEN I SELECT COLOURS FOR MY RGB/RGBW STRIP, THEY ARE ALL WRONG

Reason:

Yous have crossed over the cables into the controller. If yous take wired the Red cable into the Blue last and the Bluish cable into the Red terminal on the controller, for case, then whenever y'all select a colour on your controller the colours volition be mixed wrongly, so y'all'll come across dissimilar low-cal colours to those y'all've selected.

Solution:

Yous must check the cables, and re-wire any that are crossed over into the correct terminals. If you have extended the cable with a cablevision connector yous must also check those connections too.

Sometimes the cables can exist touching, which tin create unpredictable results. If Carmine and Blue cables are touching, for example, then you'll demand to separate them then the connections are pure and without interference.

Share this folio!

How To Repair Led Light Strip,

Source: https://www.instyleled.co.uk/support/troubleshoot-led-strip-lights/

Posted by: alkirehonpon.blogspot.com

0 Response to "How To Repair Led Light Strip"

Post a Comment